ETEK Parking has implemented a 2-level smart puzzle parking system at the Phu Dong Sky Garden project, effectively solving the challenge of limited parking space.

Completion of training facilities at Can Tho Vocational College

Successful research, design, and construction of rooms: Basic technical room; Basic electrical room; Equipped electrical practice room; Electrical machine practice room; Electrical installation practice room; Automation practice room serving practical training for students and lecturers.

Introduction to Can Tho Vocational College

As one of the key high-quality educational institutions with a scale of over 5000 students, the college offers various levels of education such as college, intermediate, vocational training with the standards of advanced countries in the world, towards standardization, modernization, socialization, and international integration, contributing to meeting the demand for high-quality human resources for the industrialization and modernization of the country.The college currently focuses on training in Electronics; Mechanical Engineering; Hydraulic, Electrical, Information Technology, Refrigeration, and some other hot fields such as Fashion Design, Accounting, Construction with the aim of becoming a high-quality international vocational training center.

To achieve its goals, the college aims to train comprehensive, ethical, knowledgeable, healthy human resources with professional skills to adapt to the changes of the market mechanism, and contribute to the country's development. The college always ensures complete and perfect infrastructure to meet the teaching and future goals.

Cooperation between ETEK and the college

ETEK Automation Solutions Joint Stock Company and Can Tho Vocational College have many opportunities to cooperate together for mutual development such as organizing seminars or accepting college students for internships and work at the company.ETEK collaborates with the college to provide internship opportunities for students to apply their knowledge in practice and gain real-world work experience.

The relationship is also reflected in designing training programs to meet the practical needs of the automation industry. This helps students acquire skills suitable for labor market requirements.

Requirements for building training laboratories

During the research, design, and implementation of vocational training laboratories, Can Tho College sets out some requirements to perfect the equipment at the college:Requirements for infrastructure design

Can Tho Vocational College requires ETEK to design laboratories suitable for specific majors according to the plan. Constructing and completing to ensure safety for students and lecturers during practice.Requirements for technique

ETEK ensures that training equipment products meet the requirements of the college. Additionally, providing complete documentation and instructions for usage during technology application in training or technical support for teachers and students to use effectively.Cooperation between universities and businesses in building training laboratories not only benefits students but also creates an advanced and practical learning environment.

Difficulties in the research, design, and construction process

Balancing construction costs and ensuring complete equipment products is the key to success and progress of the project.- Building training laboratories requires significant funding for equipment procurement, infrastructure, and construction.

- Sometimes, there may be difficulties in finding suitable space to build new laboratories or expand existing ones.

- Old facilities may need improvement or repairs, and developing training laboratories may face challenges due to changing requirements of existing infrastructure.

- Building and completing training laboratories may take considerable time, delaying the implementation process.

- The college has fixed study schedules, so changing spaces or implementing new laboratories may cause inconvenience to ongoing teaching programs.

- Project management for building training laboratories requires management skills and coordination from various departments within the college.

- Continuous investment in updating new technologies and modern equipment may require constant investment and close cooperation with industry partners.

- Ensuring safety for students and compliance with relevant safety and environmental regulations can be a major challenge when building training laboratories.

Achievements

With available resources and experienced engineers, ETEK quickly engaged in research and implementation of laboratories to ensure timely completion and rapid operation.- Basic technical room

- Basic electrical room

- Equipped electrical practice room

- Electrical machine practice room

- Electrical installation practice room

- Automation practice room

Let's review some of the training laboratories that ETEK has built at Can Tho Vocational College:

Safety practice model after using safety shoes

Safety electrical practice model

Mobile scaffolding safety practice model

Safety practice model in enclosed rooms

Transformer station safety practice model

Safety practice model when using safety helmets

6-axis robot training model

Elevator training model

Central air conditioning model

Industrial electrical practice table

Others Projects

ETEK has successfully implemented a project to supply and install 5 Markem-Imaje 9750+ industrial inkjet printers for an electronic components factory. The project's goal is to replace old printing equipment and meet the increasing requirements for resolution and accuracy in printing micro QR codes on electronic products.

ETEK implemented the Pick to Light system for 15 Kitting areas and 7 Sequencing areas with a total of 3,575 components, reducing picking time, reducing errors and increasing productivity. The project included mechanical and electrical installation, integration with the manufacturing management system (MES) and operator training. The result: increased operational efficiency, synchronized data management, stable operation, meeting the high requirements of the automotive industry.

Client: A Japanese enterprise specializing in the production of auxiliary equipment for automobiles and motorcycles

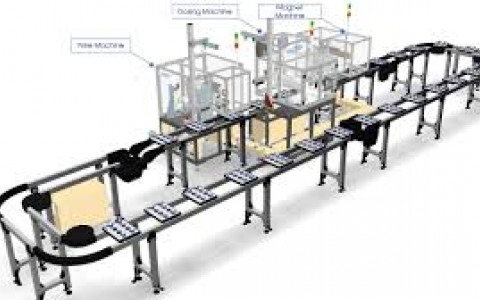

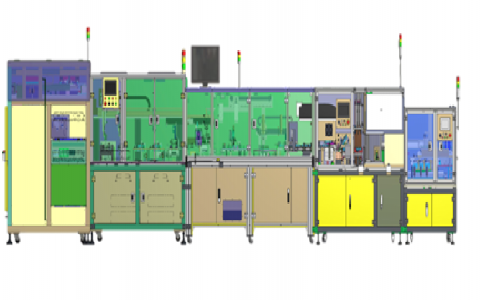

Quantity: 01 assembly line

Project Name: Supply of Speaker Assembly Line

Quantity: 01 assembly line

Project Name: Supply of Speaker Assembly Line

Through nearly 15 years of cooperation and continuous learning from our Customers, ETEK has matured significantly in technical capability and has also achieved comprehensive improvement in processes, management mindset, and working culture. From the early, challenging projects to now, ETEK is honored to be a supplier of numerous machines and production lines, providing various specialized automation equipment for key stages in the industrial manufacturing process.

With the orientation of "long-term development with customers, built on technical expertise and sustainable responsibility," we are proud to continue our collaboration with a leading Japanese electronics partner on the Paper Roll Assembly Machine project – a challenging endeavor that stands as a testament to the trust and strong bond between our two companies

Client: A sports eyewear manufacturing company in China

Quantity: 01 machine

Machine Name: Anti-Fog Coating Machine for Swimming Goggles

Quantity: 01 machine

Machine Name: Anti-Fog Coating Machine for Swimming Goggles

_cr_480x300.png)

ETEK implemented an AGV (Automated Guided Vehicle) system for an automotive manufacturing and assembly plant, aiming to fully automate the transportation of materials, pallets, and trolleys throughout the production line.

ETEK's automated palletizer system for 30L KEGs boosts production capacity to 400 KEGs/hour, minimizes manual labor, optimizes the process, and ensures stable, 24/7 operation with flexible settings for operational adjustments.

ETEK's automated pump cap tightening line boosts production speed, ensures consistent quality, and reduces operational costs while enhancing real-time defect detection and product removal during the production process.

The automatic parking system maximizes the use of space across 3 underground levels, increasing parking capacity compared to traditional lots.

A semi-automatic parking system was deployed throughout all four basement levels, featuring a 2-level puzzle parking solution in each designated basement zone

This model of automated product sampling serves not only as an innovative distribution channel, but also as a promising source of revenue for individual investors and product distributors.

_cr_480x300.png)

Case Study: ETEK Implements an Automated Production Line Training Solution at Thai Nguyen University of Technology

The semi-automatic 3-level puzzle parking system combined with a 2-level motorbike lift is an optimal parking model in terms of space utilization, operational efficiency, and cost-effectiveness.

Our client is one of the leading corporations in the food and beverage industry, operating a high-capacity potato snack production line. To ensure product quality and meet the growing market demand, the client set strict requirements for the quality inspection system. ETEK successfully developed and implemented an automated solution for date printing and product quality inspection for the snack production line.

ETEK Parking has successfully implemented an automated parking system using Robocar technology in Quang Ninh – one of the most advanced technologies currently available in the field of automated parking.

Case Study: From Vietnam to the Philippines – Delivering a Comprehensive Refrigeration Training Solution

Case Study: ETEK Provides Technical Training Equipment for Dai Nam University

A Modern Training Solution with the Power Electronics Application Training Kit

Case Study: ETEK Equips Vietnam Vocational College Korea Ha Noi City with Advanced Training Equipment

Client: Vietnam – Korea Vocational College

ETEK and the Technical Training Equipment Project for the University and College of Technical Technology Quy Nhon

_cr_480x300.png)

The project was implemented to create a training environment that closely simulates the actual procedures and conditions of an automotive assembly line.

ETEK has successfully built a fully automatic bagging line, with a total output of up to 1200 bags/hour. The automated system includes a range of advanced equipment and technologies from automated conveying systems to bag printers, automated information checking and weight checking systems, along with detection and elimination capabilities Remove error envelopes.

ETEK has successfully researched, designed, and constructed a Distributed Control System (DCS) training laboratory for the Electrical Engineering Department of the Hanoi University of Industry.

_cr_480x300.jpg)

ETEK successfully constructed the thermal laboratory and industrial automation laboratory for Vinh Long University of Technical Education.

Our journey with Unilever factories in Vietnam, Indonesia, and the Philippines is a story of creating sustainable and professional automation solutions for fully automated consumer goods production lines, ensuring hygiene, safety, and aesthetics...

A manufacturer of children's boxed milk products in Da Lat aims to automate their product packaging lines to improve productivity, enhance efficiency, reduce costs, and eliminate the possibility of quality issues due to human error.

Driving digital transformation projects and focusing on building smart factories and intelligent supply chain management is the strategy of Unilever Vietnam.

The soft drink manufacturing plant has built a packaging line to increase production output with twist conveyance technology for the first time introduced in Vietnam.

ETEK has completed the production and installation of the semi-automatic parking system project with 1,000 mechanical parking positions at the Symphony complex after nearly 7 months of construction.

_cr_480x300.jpg)

_cr_480x300.png)