Packaging line for soft drinks 48.000 units/hour

The soft drink manufacturing plant has built a packaging line to increase production output with twist conveyance technology for the first time introduced in Vietnam.

Our client is a beverage manufacturing plant providing a variety of product lines to the consumer market in Vietnam. These products are available in various outlets ranging from supermarkets, shopping centers to convenience stores, retail outlets in all 64 provinces and cities. The brand holds up to 35% market share with 2 manufacturing plants directly in Vietnam. After the Covid pandemic, the soft drink market became fiercely competitive, bringing challenges that created pressure and motivation for the plant to adapt. ETEK provides an automated packaging line solution for the client's plant.

The production line consists of many different stages, creating demands for corresponding automated machines. The combination of production modules includes:

During the mass project implementation, challenges arise due to the new twist technology, requiring repairs, improvements, and upgrades to ensure smooth production line operation. Despite careful planning in the design phase, during project implementation, ETEK engineers still face various challenges:

Issues Facing the Beverage Manufacturing Plant

Product Output

Post-Covid, despite economic difficulties, there was a significant increase in consumer goods consumption and beverage production. Therefore, the plant's urgent need for product output became a top priority to serve sales and dominate the market. Additionally, there is a need for diverse product lines as well as trends favoring safety and health for consumers.Aesthetic Requirements

Continuous competition drives changes and adaptations for the beverage manufacturing plant to develop. This includes both imported products from Japan, South Korea, Thailand, etc., and domestically produced items. Combining various factors, the plant needs to change both the quality and aesthetics of the products. Packaging, labels, designs, varieties, flavors of the product lines need to be professional, consistent, and increasingly attractive.Product Quality

Product quality is always a top priority to attract savvy customers. Just one defective product released into the market can significantly impact the company's reputation, value, and profits. Therefore, ensuring product quality control is an ongoing challenge that the plant needs to continuously improve.Digitization of the Beverage Manufacturing Plant

The digitization of the plant is a common policy pursued by countries, including Vietnam. Our client is a leading company in the trend towards automation and digitization of manufacturing plants in the soft drink industry.

Requirements of the Beverage Manufacturing Plant

Automation

- The plant is currently using 100% manual labor for sorting and packaging bottled soft drinks. Some issues the plant is facing include:

- Increased production volume with insufficient labor.

- Overtime to meet production demands leading to fatigue and lack of focus among workers.

- Diverse packaging methods leading to errors when executed manually.

- Ensuring food safety and hygiene standards in soft drink production.

Technology

- In the path to constructing a modern 4.0 plant, automating the beverage production line is both the first and most crucial step. The plant's requirements for implementing and executing digitization include:

- Connecting production lines.

- Transmitting work signals.

- Quality monitoring.

- Process supervision.

Soft Drink Production Efficiency

As mentioned earlier, the main issue facing the plant is increasing product output. Hence, the plant's firm requirement is to meet production targets.Challenges

Total Line Contractor

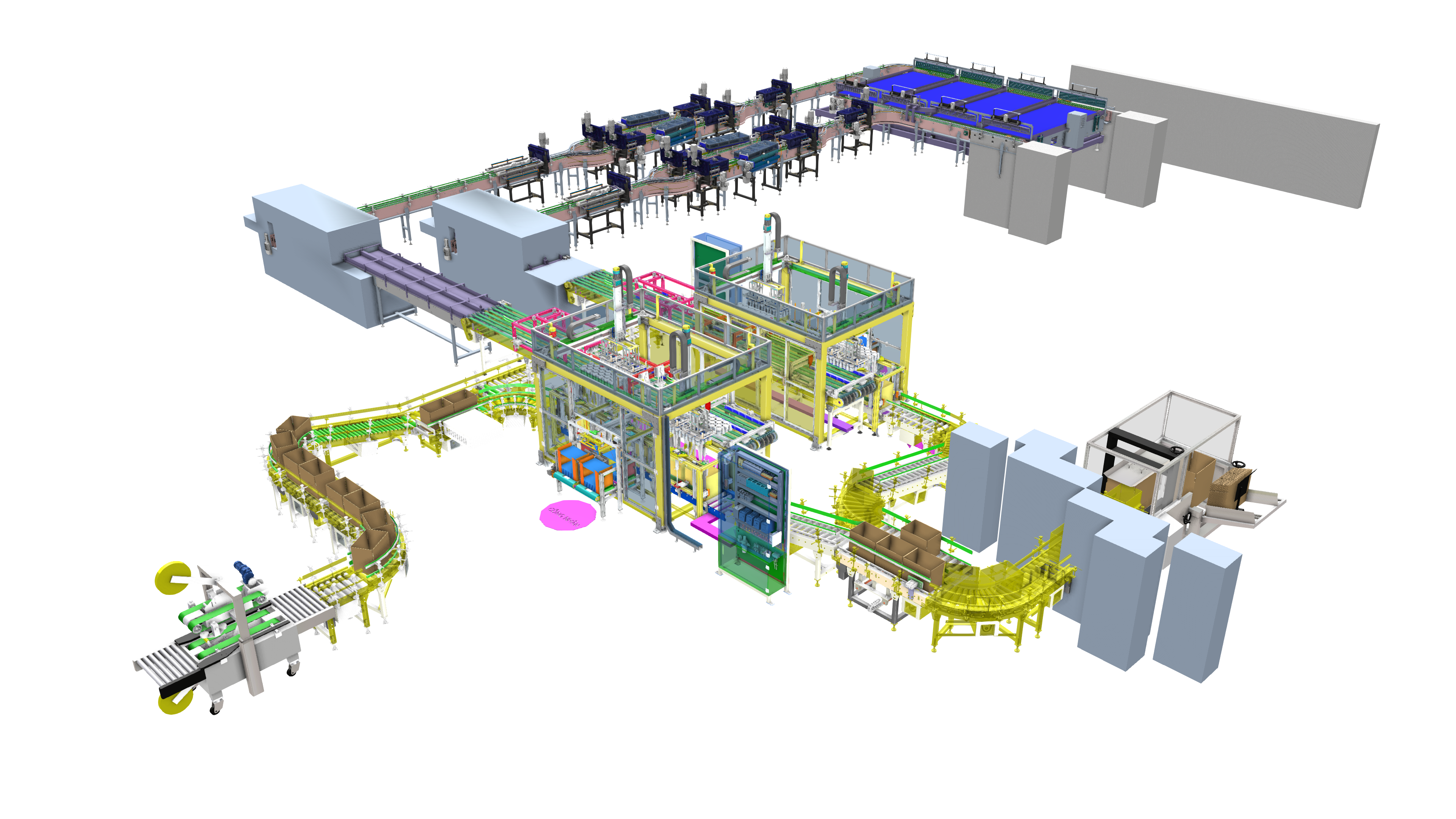

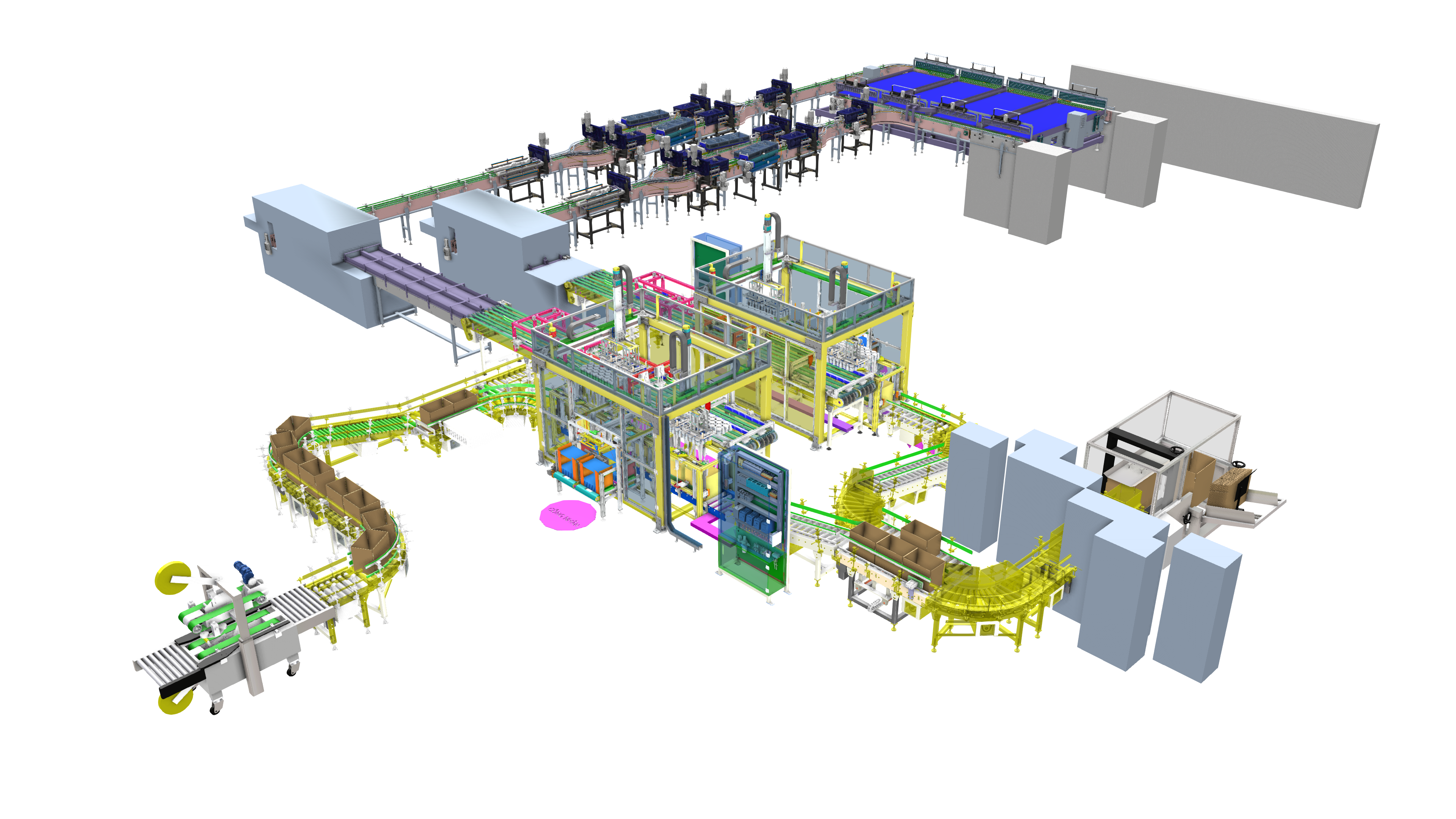

Developing a comprehensive automation solution for the beverage production and packaging line sorting process. ETEK identifies this as a crucial project that receives special attention from the client in terms of scale and project value.The production line consists of many different stages, creating demands for corresponding automated machines. The combination of production modules includes:

- Product conveyor belt.

- Twist lane divider/design.

- Twist cup flipping/design.

- Twist lane merging/design.

- Twist block formation/design.

- Heat shrink wrapping machine/standard machine.

- Case packer/grab and stack machine design.

- Straw dispenser machine/standard machine.

- Crate assembly machine/standard machine.

- Crate sealing machine/standard machine.

Technology

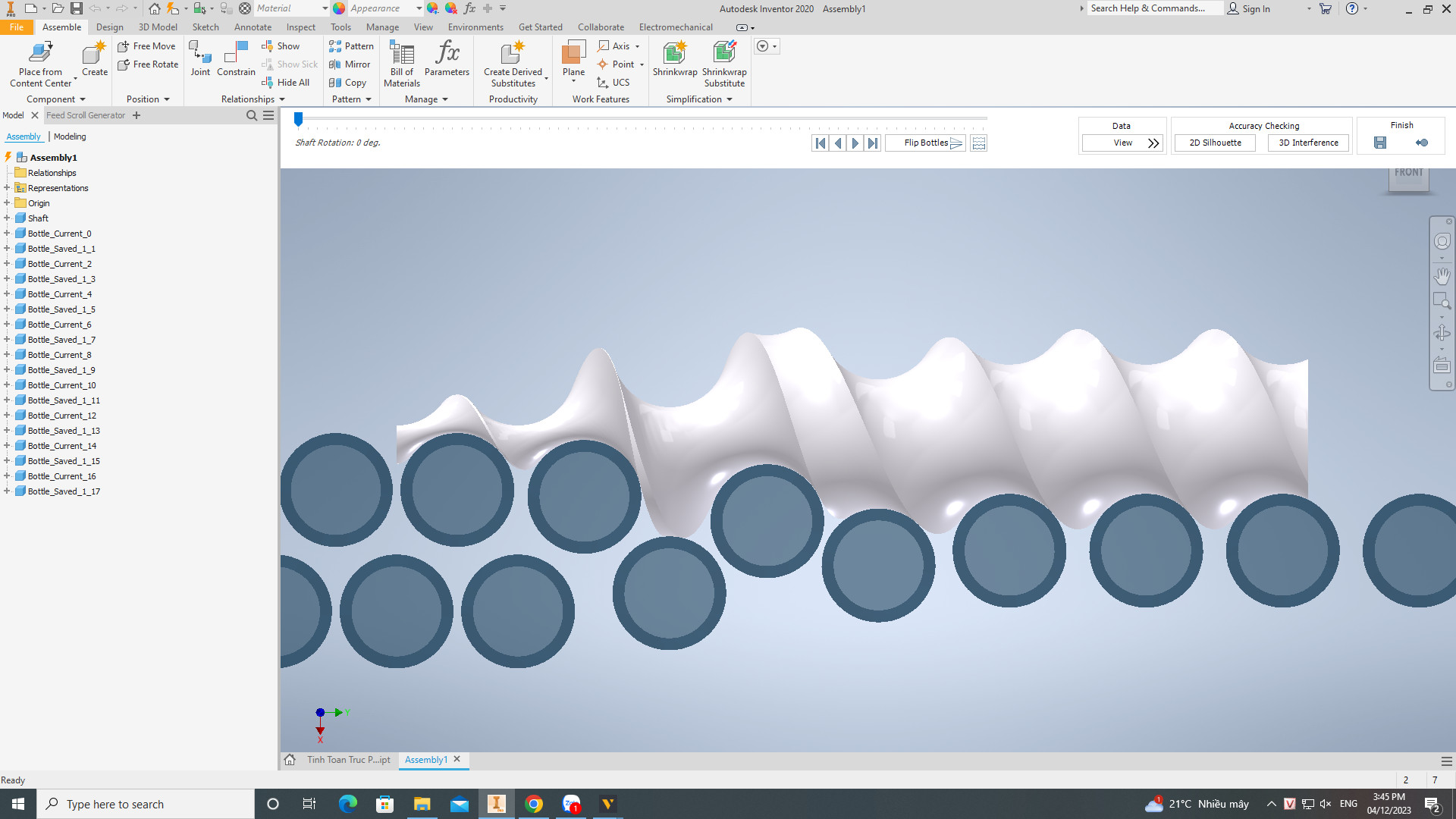

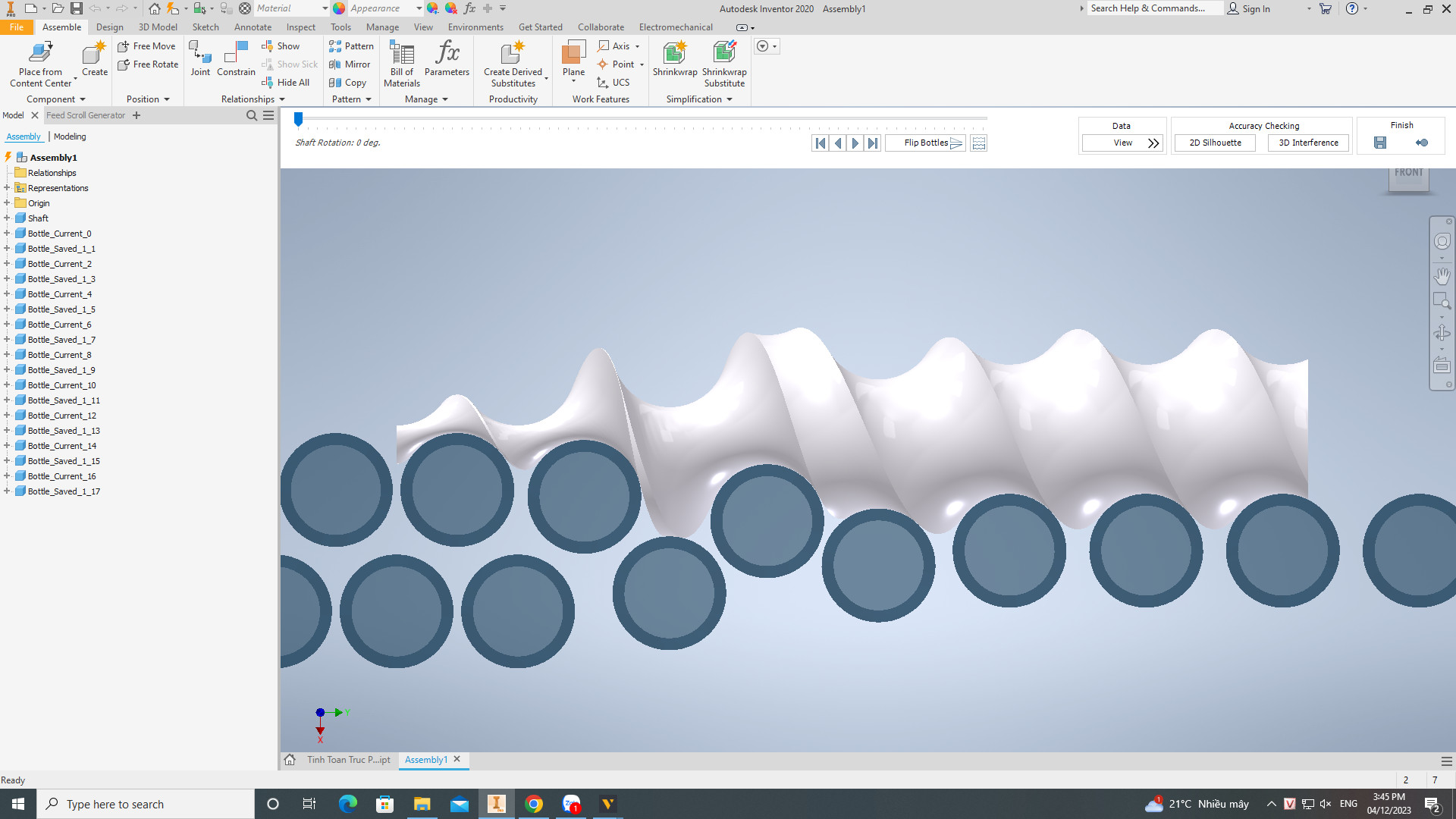

- The twist technology is applied to beverage production to meet product sorting specifically for our client's needs. It is created through four distinct stages: lane division, cup flipping, lane merging, and block formation. This technology is developed to shape the product configurations as per the client's requirements.

- The twist technology, although existing globally, is being applied for the first time in Vietnam's market. This presents a significant challenge to ETEK engineers.

- Absorbing technological knowledge poses a significant challenge, given that this is the first time and ETEK is the only unit to introduce this technology into the production line. All research and learning processes are intensive, involving rapid work and experience gathering by ETEK engineers.

- Through real-world simulation software design, ETEK experts have programmed the production line operation. However, the operation process of the production line is a simulation process, requiring independent structure design tailored for this client.

Time

From the client's request to presenting the solution, there is only a 4-week working period. All phases, including technology research, capacity calculations, equipment preparation, and overall solution development, must be simultaneously implemented to meet the deadline.Implementation

The new twist technology requires high-speed and precise beverage production, but during the product testing phase, there is a lack of equipment for trial operation. Precision machining of equipment clusters takes a long time, making trial runs difficult.During the mass project implementation, challenges arise due to the new twist technology, requiring repairs, improvements, and upgrades to ensure smooth production line operation. Despite careful planning in the design phase, during project implementation, ETEK engineers still face various challenges:

- Lane division twist:

- High conveyor belt speed leads to a large number of cups entering, combined with the liquid nature of soft drink cups, causing deviations on the conveyor belt.

- The twist shaft design with a twin-screw input on both sides creates a small input shape, causing "cutting" into the cup, damaging the product.

- The two conveyor belt interface is jammed due to the high entry speed of the cups.

- Block formation twist:

- Liquid cups prone to deformation create gaps, leading to block deviation if cups deform from 4 cups/block to 5 cups/block.

- Cups laid flat to be pressed upwards cause cup spills.

ETEK Solutions

Speed Key

ETEK confidently provides a solution for beverage production efficiency, meeting the client's requirement of 48,000 products/hour. Our engineers utilize realistic simulation software technologies, providing trust and ensuring the client's project success.

Cost Reduction in Soft Drink Production

The plant invests in a production line to reduce the cost structure of products, thereby increasing competitiveness. The production line increases output, thereby reducing labor costs, excess materials, electricity, etc., meeting the plant's requirements.Safety and Hygiene

The automated production line ensures 100% safety and hygiene standards in beverage production. Additionally, the machinery helps increase the 5S environment in the workplace.Beverage Production Automation

The practical benefits include productivity gains, production monitoring, production line automation, and minimizing errors. Thus, the client and the plant build digitization goals as previously set.Why Choose ETEK

- ETEK is a leading provider of comprehensive automation solutions for beverage production and packaging in Vietnam.

- ETEK provides top-notch technology solutions in the packaging industry for prominent clients like Unilever, Vinfast, P&G, etc.

- ETEK has a team of experienced design engineers, simultaneously implementing multiple large projects.

Benefits Achieved

- Increased productivity by 125%.

- Reduced costs by 4-8%.

- Minimized errors to less than 3%.

- Hygiene standards exceed 99%.

- Plant digitization exceeds 60%.