1. General project information

As the automotive industry pushes to automate and digitize its production lines, a major customer in the sector has partnered with ETEK to upgrade and optimize the Kitting and Sequencing areas at their plant. The project goal is to improve picking efficiency, reduce errors in the production process, and synchronize with the existing production management system to meet growing production demands.

2. Current difficulties and production scale

Notable issues:

- Long pick-up time: Workers have to manually check and compare component numbers, which is time-consuming and affects production progress.

- High error rate: Manual component inspection and validation is prone to errors, affecting production quality and assembly line reliability.

- Current component count:

The customer is managing a large volume of components in the Kitting and Sequencing areas:

| Area | Quantity |

| Total Kitting Areas | 15 |

| Total Sequencing Areas | 7 |

| Total number of event links | 3575 |

The large volume of components combined with the above problems created an urgent need for a more modern and efficient solution.

3. Customer requirements

To overcome the above difficulties, the customer has set out the following main requirements:Deploy Pick to Light system for 2 areas at the factory: Kitting & Sequencing.

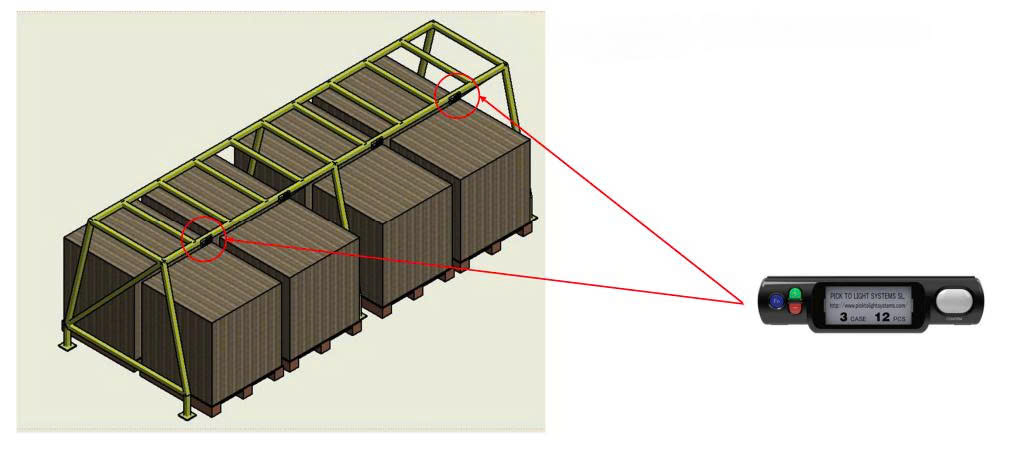

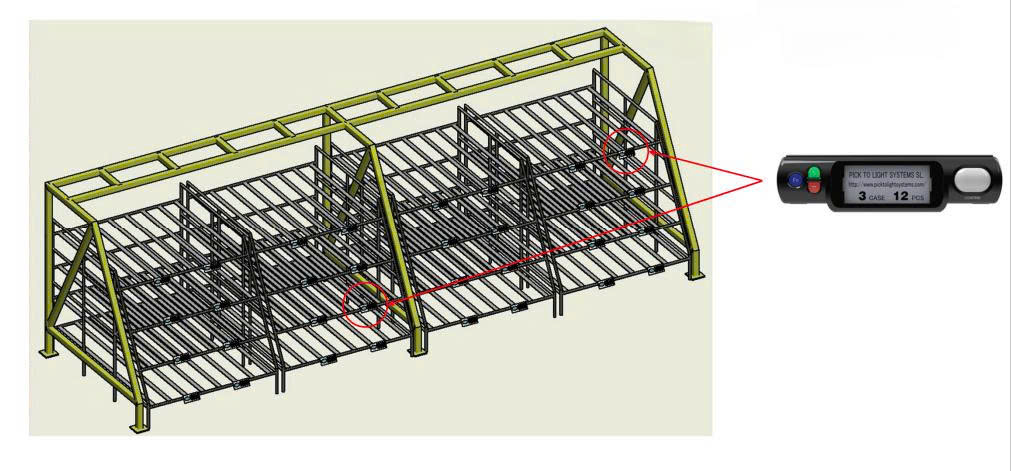

Infrastructure:

- Mechanical: Install the mounting bracket for the light modules and labels.

- Electrical system: Conduit, stack lights, junction boxes, LED display panels, etc.

- Equipment: Provide Pick to Light system and related hardware such as control computer, database server,...

- Integration: Connect the new Pick to Light system with the customer's existing manufacturing management system to ensure data synchronization and efficient management.

- Training: Instruct operations team on how to use and troubleshoot the Pick to Light system.

4. ETEK's solution

To address the above requirements, ETEK has proposed and implemented a comprehensive solution:

- Design and implement Pick to Light system for 2 areas Kitting & Sequencing, helping workers operate more intuitively, quickly and accurately.

- Complete mechanical and electrical infrastructure, including racking, conduit, junction boxes, stack lights and LED display panels, ensures stability and future expansion.

- Integrate the new system with the customer's existing manufacturing management system to synchronize data and maximize efficiency.

- Provide control equipment including computers and database servers, helping the system operate smoothly and stably.

- Train the operating team, help customers proactively handle problems and operate effectively.

5. Project implementation journey

ETEK team worked closely with the customer right from the stage of surveying the actual production process, collecting data and assessing existing problems. Then, ETEK proceeded to design details, build technical diagrams and plan implementation step by step:

- Install the Pick to Light mounting bracket and modules.

- Complete electrical, plumbing and hardware connections.

- Integrate Pick to Light software with existing manufacturing management systems.

- Synchronous testing and test execution.

- Conduct hands-on training sessions for customer operations teams.

Thanks to a methodical implementation process and experienced technical team, the project was completed on schedule and with high quality.

6. Results after the project

- Shorten picking time: Workers work faster thanks to visual guidance by lights, minimizing manual checking.

- Reduced Defect Rate: Component picking becomes more accurate, reducing errors and increasing the quality of output products.

- Increased Productivity: Processes become smoother, increasing overall productivity of the production line.

- Stable and synchronized operating system: Data is centrally managed, transparent and easy to control.

- Confident operations team: Staff can handle basic troubleshooting, minimizing production downtime and optimizing operating costs.

Learn more about the Pick to Light system: Smart Picking Solution Pick to light | Digital Picking System

ETEK's Pick to Light solution has helped customers significantly upgrade their picking process, contributing to building a modern, safe and efficient production environment that meets the strict requirements of the automotive industry.