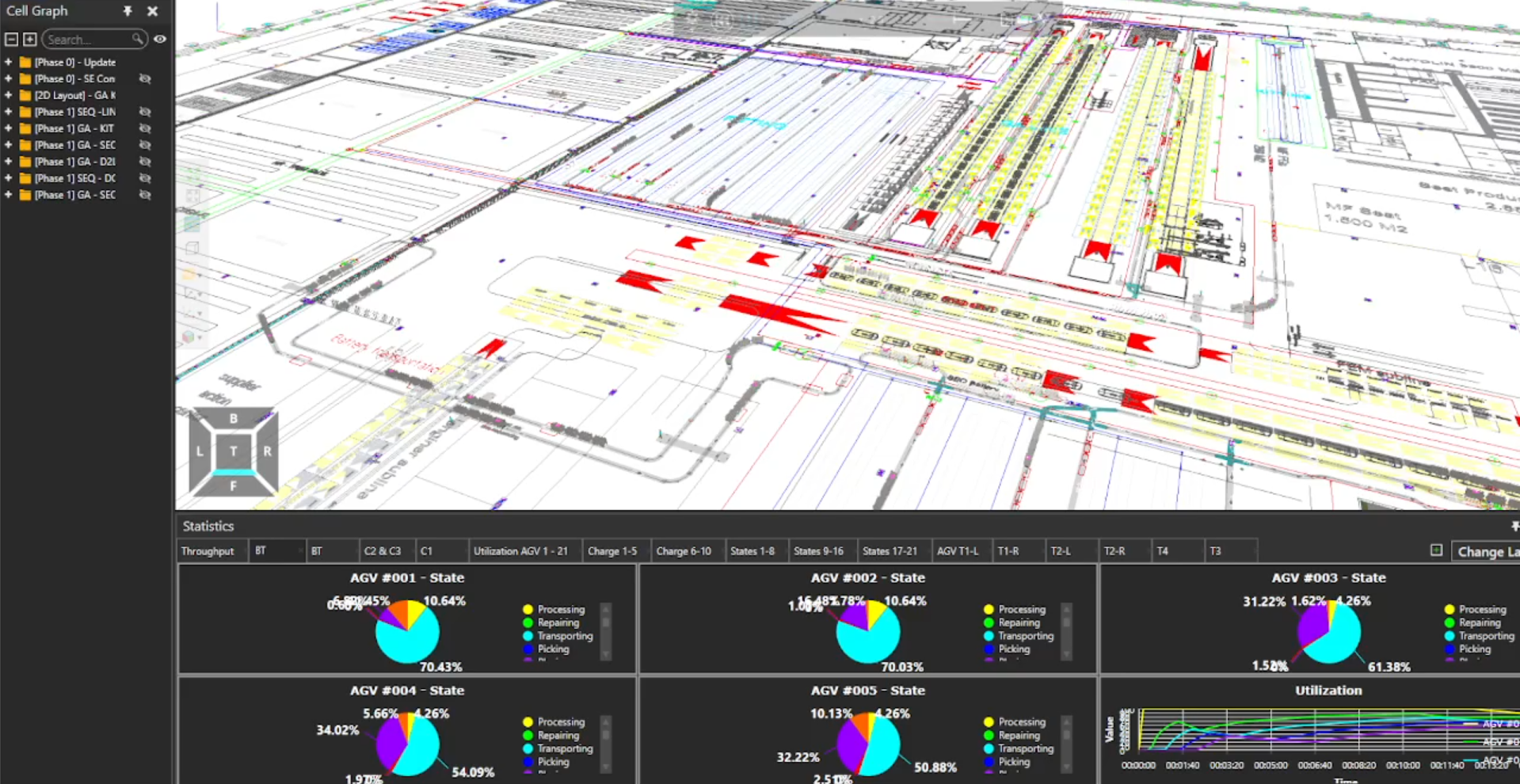

AUTOMATED MATERIAL HANDLING WITH A FLEET OF HUNDREDS OF AGVS AT AN AUTOMOTIVE MANUFACTURING AND ASSEMBLY PLANT

ETEK implemented an AGV (Automated Guided Vehicle) system for an automotive manufacturing and assembly plant, aiming to fully automate the transportation of materials, pallets, and trolleys throughout the production line.

1. Customer Introduction

The customer is one of Vietnam’s leading automotive manufacturing and assembly enterprises, operating in the fields of industrial engineering and precision mechanics. They are gradually modernizing their production line to keep pace with the global trend of smart manufacturing.

2. Customer’s Challenges

Before the AGV system was deployed, the entire process of transporting materials, components, and finished products within the factory was done manually, primarily using traditional tow tractors and human labor. Each production area had to assign a dedicated workforce for transportation tasks, which not only led to labor inefficiencies but also significantly increased operating costs.Moreover, the reliance on human labor made the material transport process unstable — errors in delivery locations, delays in supplying materials, or missed items were common, especially during peak production hours. The old operation model also couldn’t support 24/7 continuous production due to the limitations of worker shift schedules and required breaks.

In addition to reduced productivity and efficiency, manual transportation posed potential safety risks, such as collisions between workers and equipment in crowded factory environments. These challenges made it difficult for the customer to improve production efficiency, control output quality, and build a smart, modern in-house logistics system.

3. ETEK's Solution

ETEK provided a comprehensive automated transport solution, including:- Latent AGVs

- Pallet AGVs (FLMR) with 1000kg payload

- Tractor AGVs with 2000kg and 3000kg payloads

3.1. Carton Box Transportation Solution with Latent AGV CT5

Utilizing V-SLAM navigation technology combined with QR code markers, the CT5 AGV achieves precise positioning and flexible movement within the factory environment. With a payload capacity of up to 1500kg, a travel speed of 60 meters per minute, and an operating time of 6–8 hours, this AGV automates the collection and transportation of component boxes from the warehouse to the SEQ and GA lines. At the warehouse, operators simply input the pick-up and drop-off locations, and the system automatically navigates the AGV to the correct points for delivery. In the production area, staff only need to confirm and select the required box, and the AGV will deliver it to the designated station. This solution minimizes manual handling, increases operational efficiency, and enhances accuracy.3.2. AGV Solution for Automated Pallet Transport and Supply to the Production Area

This specialized AGV features a compact design, a payload capacity of up to 1000kg, and a high travel speed of up to 1200mm/s. The system supports the entire cycle—from receiving loaded pallets at the staging area, transporting them to kitting points and production lines, to collecting empty pallets and returning them to storage. The AGV automatically performs pallet pick-up and drop-off at predefined locations, equipped with signal lights and warning buzzers to ensure safety. This solution not only reduces manual handling time but also ensures a continuous and accurate material flow for production.

3.3. Trolley-Towing AGV Solution

This solution automates the transportation of heavy materials within the factory, making it especially suitable for the automotive industry. With a payload capacity of 2000–3000 kg, Visual SLAM navigation, a travel speed of 96 meters per minute, and continuous operation time of 6–8 hours, the AGV ensures efficient performance without the need for complex infrastructure.Operators simply hook up the trolleys, call the AGV, and the system will automatically tow the entire trolley convoy to the designated delivery point. This solution significantly reduces manpower, increases operational continuity and accuracy across key areas such as the warehouse (WH), kitting area (KIT), GA Line, and SEQ — contributing to higher productivity and factory modernization.

During the project implementation, ETEK faced numerous challenges—especially in ensuring the stability and precision of the AGV system within a large-scale factory environment with many complex intersections.

To meet the project's tight timeline, ETEK engineers worked tirelessly day and night, continuously monitoring, fine-tuning every technical parameter, and conducting multiple real-world tests to ensure the AGVs operated smoothly and were fully synchronized with the customer’s production process.

4. Achieved Results

ETEK’s AGV system enabled the customer to:

- Significantly reduce labor costs

- Increase transport productivity to a 24/7 operation level

- Ensure synchronization and continuity throughout the production chain

- Easily integrate with the factory's management system