Unilever builds smart factory, digitalizes supply chain

Driving digital transformation projects and focusing on building smart factories and intelligent supply chain management is the strategy of Unilever Vietnam.

Unilever Vietnam's digital transformation journey began in 2019 with the vision of becoming a leading consumer goods company in Vietnam in terms of digital transformation. Specifically, digitalization efforts in production and distribution chains were set with specific goals, timelines, and plans.

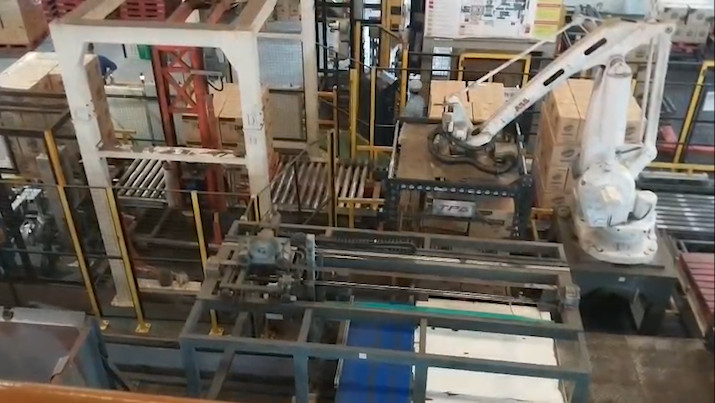

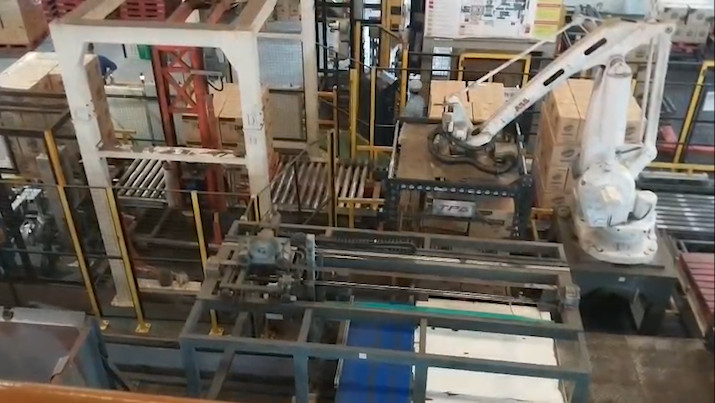

First and foremost, the company is digitizing the entire production and supply chain. The system integrates Internet of Things (IoT), artificial intelligence (AI), and super applications to connect all activities on a single platform. This enables a 10x acceleration in operations throughout the chain, handling large volumes of data and tasks. As a crucial link in the transformation from business plans to final products delivered to customers, Unilever's factories not only automate production lines but also aim for smart factory models and robotics.

As a crucial link in the transformation from business plans to final products delivered to customers, Unilever's factories not only automate production lines but also aim for smart factory models and robotics.

At the same time, the company is also moving towards real-time operations to immediately respond to customer and market needs. Company representatives noted that this is a significant goal of the supply chain that consumer goods companies worldwide are aiming for.

To achieve these goals, Unilever Vietnam proactively invests in digital talents by attracting talent, providing deep training, and implementing key projects. Vietnam is one of the first markets where Unilever has established a specialized digital transformation expert group, internally training over 300 data analysts, and fostering a digital transformation movement across departments. Beyond just digitization, the company also aims to imbue a digital transformation mindset throughout its activities and departments. Digitalization is seen as Unilever's competitive advantage to drive superior performance and human development, preparing for future trends and opportunities.

Beyond just digitization, the company also aims to imbue a digital transformation mindset throughout its activities and departments. Digitalization is seen as Unilever's competitive advantage to drive superior performance and human development, preparing for future trends and opportunities.

Mr. Pham Manh Tri, Vice President in charge of Supply Chain at Unilever Vietnam, stated that from the perspective of a consumer goods company closely tied to millions of Vietnamese families, digital transformation helps Unilever fuel most activities, motivating enhanced production capacity and the company's position. Additionally, digital transformation helps the company effectively reach customers and creates conditions for developing human resources in line with future trends.

"We will continue to develop and further accelerate the digitalization journey, complete the smart factory and supply chain goals, contributing to the National Digital Transformation Program initiated by the Prime Minister," Mr. Tri said."

First and foremost, the company is digitizing the entire production and supply chain. The system integrates Internet of Things (IoT), artificial intelligence (AI), and super applications to connect all activities on a single platform. This enables a 10x acceleration in operations throughout the chain, handling large volumes of data and tasks.

At the same time, the company is also moving towards real-time operations to immediately respond to customer and market needs. Company representatives noted that this is a significant goal of the supply chain that consumer goods companies worldwide are aiming for.

To achieve these goals, Unilever Vietnam proactively invests in digital talents by attracting talent, providing deep training, and implementing key projects. Vietnam is one of the first markets where Unilever has established a specialized digital transformation expert group, internally training over 300 data analysts, and fostering a digital transformation movement across departments.

Mr. Pham Manh Tri, Vice President in charge of Supply Chain at Unilever Vietnam, stated that from the perspective of a consumer goods company closely tied to millions of Vietnamese families, digital transformation helps Unilever fuel most activities, motivating enhanced production capacity and the company's position. Additionally, digital transformation helps the company effectively reach customers and creates conditions for developing human resources in line with future trends.

"We will continue to develop and further accelerate the digitalization journey, complete the smart factory and supply chain goals, contributing to the National Digital Transformation Program initiated by the Prime Minister," Mr. Tri said."